|

Membrane Separation used for PAA (Phenoxy acetic acid) recovery from Penicillin Production.

PAA is the midbody combined by medicine+pesticide+spice. It is used for medicine production of Penicillin, Dibazole.

Ethyl chlorophenyl acetate was made after PAA Chlorination/Lipidation, it is to be used for production of phenthoate or phenthoate elthyl. which are broadspeetrum organic pesticides.

PAA is also a kind of growth hormone, which are widely available from grape, strawberry, coco, green tea and honey. at low concentration it smells like sweet honey. and PAA is an important spice, PAA also has bactericidal effect.

Appearance: white powder with special smell.

Melting Point: (℃) 76.5

Relative Density(H2O=1):1.09(77℃)

Boiling Point(℃):265.5

Molecular Formula:C8H8O2

Molecular Weight:136.15

Dissolubility:Slightly soluble in water, soluble in ethyl alcohol/diethyl ether/ammonium hydroxide.

Before 2018, the treatment process of Penicillin G K salt mother liquid is: firstly add Penicillin lyase. splitting the Penicillin G K salt into 6-APA and thyl chlorophenyl acetate. then PAA extracted by butyl acetate. adjust the pH value to 9-10.5, the PAA become PAA Solidum, and evaporate it under normal pressure at of 100-110℃ to get Degreasing Fluid. And after evaporation crystallization and crystal weight melting, they liquid will be back to Penicillin fermentation section process.

This Treatment process may require much of activated carbon and H2O2, which increases the operation cost. and due to the smelly mother liquid after crystallization. instead directly Discharge it has to be burned. they whole system is complicated with many liquid waste.

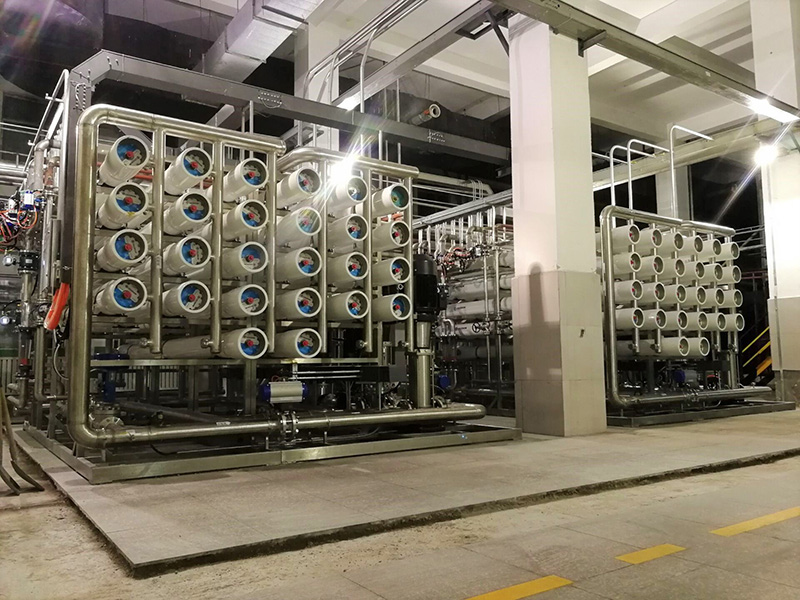

In 2019, Crossflow industrialized the Penicillin G K salt mother liquid PAA Membrane Purification Recovery system, we greatly improve the recovery rate of PAA, reduce the operation cost. enable a less harm to the environment.